We independently evaluate all recommended products and services. Any products or services put forward appear in no particular order. If you click on links we provide, we may receive compensation.

In choosing the best pocket knife the type of steel used in the blade is going to be a big factor to consider. Alongside edge geometry and design, blade steel is a critical element that determines how a knife performs. Steel is essentially an alloy (i.e. a mix) of carbon and iron that is often enriched with other elements to improve certain characteristics depending on the desired application.

In choosing the best pocket knife the type of steel used in the blade is going to be a big factor to consider. Alongside edge geometry and design, blade steel is a critical element that determines how a knife performs. Steel is essentially an alloy (i.e. a mix) of carbon and iron that is often enriched with other elements to improve certain characteristics depending on the desired application.

In the knife industry different types of steel are created by varying the types of additive elements as well as how the blade is rolled and heated (i.e. the finishing process). Refer to our Knife Steel Composition Chart for more details on these elements.

TLDR: Our Favorite Knife Steels

- CPM-S90V (Edge Retention) : See CPM-S90V knives

- CPM-S35VN (Value) : See CPM-S35VN knives

- 14C28N (Budget) : See 14C28N knives

The five key properties of knife steel

Ultimately, the different types of steel used in knife blades each exhibit varying degrees of these five key properties:

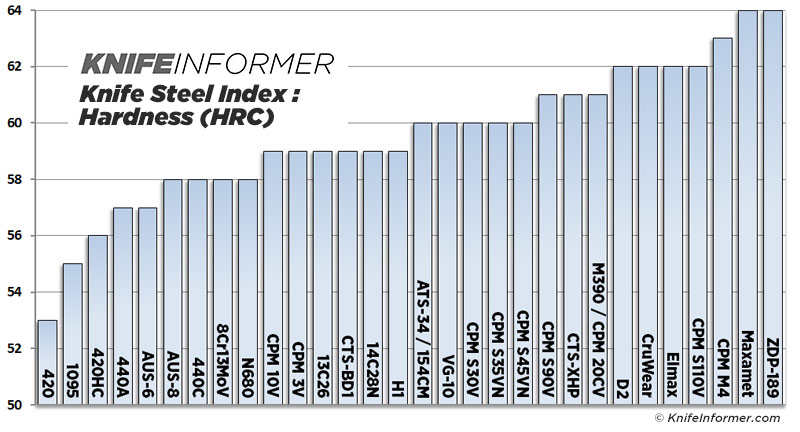

Hardness

![]() Hardness is the ability to resist deforming when subject to stress and applied forces. Hardness in knife steels is directly correlated to strength and is generally measured using the Rockwell C scale (aka “HRC”).

Hardness is the ability to resist deforming when subject to stress and applied forces. Hardness in knife steels is directly correlated to strength and is generally measured using the Rockwell C scale (aka “HRC”).

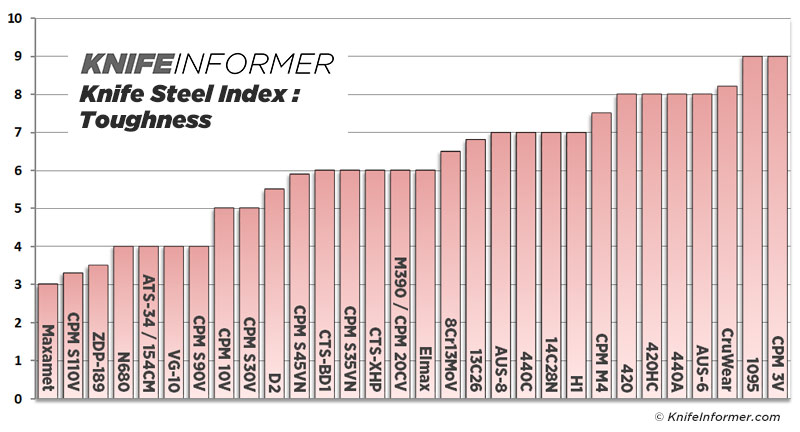

Toughness

![]() Toughness is the ability to resist damage like cracks or chips when subject to impact or “sudden loads”. Chipping is a knife’s worst enemy and never easy to fix. There are a number of different ways to measure toughness (i.e. Charpy, Izod) thus it’s less standardized than hardness when it comes to knives. In general, the harder the steel the less tough it’s likely to be.

Toughness is the ability to resist damage like cracks or chips when subject to impact or “sudden loads”. Chipping is a knife’s worst enemy and never easy to fix. There are a number of different ways to measure toughness (i.e. Charpy, Izod) thus it’s less standardized than hardness when it comes to knives. In general, the harder the steel the less tough it’s likely to be.

Wear Resistance

![]() Wear resistance is the steel’s ability to withstand damage from both abrasive and adhesive wear. Abrasive wear occurs when harder particles pass over a softer surface. Adhesive wear occurs when debris is dislodged from one surface and attaches to the other. Wear resistance generally correlates with the steel’s hardness but is also heavily influenced by the specific chemistry of the steel. In steels of equal hardness, the steel with larger carbides (think microscopic, hard, wear resistant particles) will typically resist wear better. However, carbides can become brittle and crack, thus decreasing toughness.

Wear resistance is the steel’s ability to withstand damage from both abrasive and adhesive wear. Abrasive wear occurs when harder particles pass over a softer surface. Adhesive wear occurs when debris is dislodged from one surface and attaches to the other. Wear resistance generally correlates with the steel’s hardness but is also heavily influenced by the specific chemistry of the steel. In steels of equal hardness, the steel with larger carbides (think microscopic, hard, wear resistant particles) will typically resist wear better. However, carbides can become brittle and crack, thus decreasing toughness.

Corrosion Resistance

![]() Corrosion resistance is the ability to resist corrosion such as rust caused by external elements like humidity, moisture and salt. Note that a high resistance to corrosion does involve a sacrifice in the overall edge performance.

Corrosion resistance is the ability to resist corrosion such as rust caused by external elements like humidity, moisture and salt. Note that a high resistance to corrosion does involve a sacrifice in the overall edge performance.

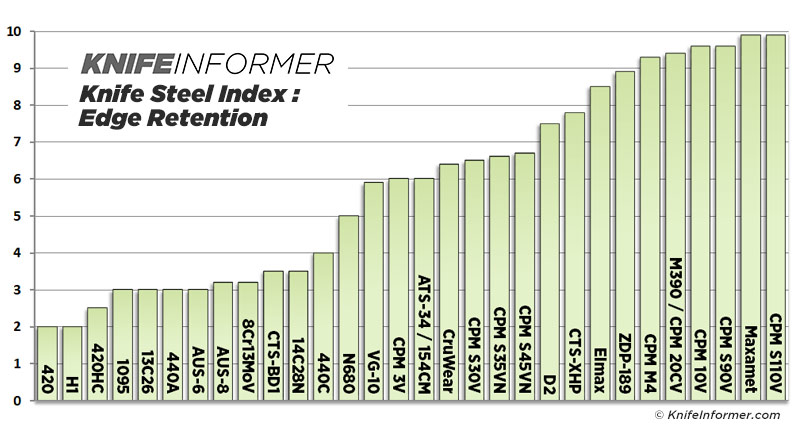

Edge Retention

![]() Edge Retention represents how long the blade will retain its sharpness when subject to periods of use. It’s what everyone talks about these days but unfortunately the measurement of edge retention lacks any defined set of standards and so much of the data is subjective. For me, edge retention is a combination of wear resistance and an edge that resists deformation.

Edge Retention represents how long the blade will retain its sharpness when subject to periods of use. It’s what everyone talks about these days but unfortunately the measurement of edge retention lacks any defined set of standards and so much of the data is subjective. For me, edge retention is a combination of wear resistance and an edge that resists deformation.

>Here’s a knife with the best performing steel for edge retention<

Unfortunately the “best knife steel” is not simply a case of maximizing each of the properties above….it’s a trade off. The biggest trade off is balancing strength or hardness with toughness. Some blades can be made to be exceptionally hard but will chip or crack if you drop them onto a hard surface. Conversely a blade can be extremely tough and able to bend but will struggle to hold it’s edge. Basically, the stuff that makes steel strong (high amount carbon/carbides) generally lowers the toughness. Also note that the term ‘stainless steel‘ is generally misleading as most all types of steel will show some kind of discoloration if left exposed to the elements for long enough. By knowing how you plan to use the knife you will generally be able to determine the best steel for your situation.

![]()

Common Knife Steel Types

The most common blade steel types generally fall into the following categories:

- Carbon Steel – generally made for rough use where toughness and durability is important. Common in survival knives and machetes. They take a sharp edge and are relatively easy to re-sharpen. The trade-off is being more prone to corrosion given the low chromium content. The most popular carbon knife steel is 1095.

- Tool Steel – primarily hard steel alloys used in cutting tools. Some popular tool steels in this group include D2, O1 and Crucible’s CPM series (i.e. CPM 3V) plus more advanced high speed steels like M4.

- Stainless Steel – basically carbon steel with added chromium to resist corrosion and other elements which increase performance levels but usually at the expense of inferior toughness. Easily the most popular category today for EDC knives and includes the 400, 154CM, AUS, VG, CTS, MoV, Sandvik and Crucible SxxV series of steels. Note that to qualify as a true stainless steel there must be at least 13% chromium.

Today’s popular knife steels

Below are the most common steels found in knife blades today. Yes, technically there are “better” steels out there (CPM-125V, CPM-10V, K294 to name a few) but these are extremely rare in the marketplace. Don’t get too carried away with the perceived rankings, it’s not an exact science and this is simply my way of bucketing the steels into general performance categories based on a variety of factors.

![]()

Quite simply the ultimate in wear resistance and edge retention in ‘mainstream’ knife production. Still relatively rare in the marketplace and arguably indistinguishable from CPM-S90V outside of the laboratory, but the fact remains that nothing holds an edge like Crucible’s CPM-S110V. It’s costly, a bitch for knifemakers to work with and sharpening can drive you nuts but a CPM-S110V blade will hold up for a ridiculous amount of time (our review of the Spyderco Military demonstrates perfectly). >> See knives with CPM-110V steel.

Crucible’s CPM S90V steel approaches the very pinnacle of wear resistance and edge retention. As you’d expect the carbon content is very high but the secret here is the extreme quantities of vanadium, almost three times that found in Elmax or S30V. Yes it’s ridiculously expensive, and yes it requires the patience of a saint to sharpen but outside its less common cousin CPM-S110V (see above) nothing holds an edge or withstands abrasion quite like CPM S90V. One of the hottest CPM S90V blade’s right now is the Benchmade 940-1 with exceptional performance. >> See knives with CPM-S90V steel.

M390 is one of the new super steels on the block, manufactured by Bohler-Uddeholm (result of merger of Austrian Bohler and Swedish Uddeholm). It uses third generation powder metal technology and developed for knife blades requiring excellent corrosion resistance and very high hardness for excellent wear resistance. Chromium, molybdenum, vanadium, and tungsten are added to promote sharpness and outstanding edge retention. Unlike ZDP-189 most carbides are formed by vanadium and molybdenum, leaving more ‘free chromium’ to fight corrosion. M390 hardens to 60-62 HRC. Bohler calls this steel “Microclean” and it can be polished to achieve a true mirror. Moderately difficult to sharpen, but won’t take you as long as with S90V. Benchmade’s 581 Barrage is an affordable example of M390 performing at its best. >> See knives with M390 steel.

ZDP-189 by Hitachi is another of the newer super steels containing huge quantities of carbon and chromium that result in ridiculous levels of hardness. ZDP-189 averages around 64 HRC but some knifemakers are able to achieve upwards of 66 HRC. Of course with those levels of hardness you can expect superb edge retention but at the cost of extreme difficulty in sharpening. With a chromium content of around 20% you’d expect it to be immune to corrosion right? Wrong. The massive amount of carbon in ZDP-189 effectively ‘pairs up’ with the chromium to form carbides which leaves less ‘free chromium’ to battle corrosion. So, while it’s both harder and more wear resistant than S30V it’s more prone to corrosion. Spyderco’s Dragonfly 2 is a good example. >> See knives with ZDP-189 steel.

European Uddeholm (now Bohler-Uddeholm) introduced Elmax which is a high chromium-vanadium-molybdenum alloyed powdered steel with extremely high wear and corrosion resistance. Elmax is stainless but acts in many ways like a carbon steel. You get superb edge holding and the easiest of the super-steels to sharpen while maintaining a healthy resistance to rust. The ‘best all round’ knife steel? Perhaps. What’s great to see is that Bohler-Uddeholm sure is giving Crucible a run for their money these days. The GiantMouse ACE Atelier is a great example of a superb Elmax blade. >> See knives with Elmax steel.

CPM-20CV is Crucible’s version of Bohler’s popular M390 steel which also influenced Carpenter to copycat with CTS-204P. As a Powder Metallurgy (PM) tool steel, you get a combination of impressive wear resistance and edge retention plus the added benefit of being highly corrosion resistant due to high levels of chromium. It’s still fairly new in the market but makers like Benchmade are already using CPM-20CV in newer models like their 556-1 Griptilian. In fact, Benchmade claim their M390 is marginally tougher but 20CV has better edge retention. >> See knives with CPM-20CV steel.

CTS-XHP from US based Carpenter is another relatively new knife steel that has very good edge retention and hardens to about 61 HRC. This is yet another powder metallurgy creation where Carpenter’s technicians have developed an extremely fine powder grain that results in excellent performance. Slightly better edge retention than S30V and but a little more work required in the sharpening process. Think of CTS-XHP as a more corrosion resistant form of D2 steel with marginally superior edge retention. Like D2, however, it’s not easy to sharpen and can be brittle (prone to chipping). >> See knives with CTS-XHP steel.

A high performance tool steel which excels at toughness and arguably holds and edge better than any other carbon steel. Like all CPM steels, CPM M4 is created using Crucible’s patented Crucible Particle Metallurgy process, which provides an extremely homogeneous, stable and grindable product compared to the traditional processes. CPM M4 provides superbly balances levels of abrasion resistance and toughness through high doses of molybdenum (hence the “M”), vanadium and tungsten together with reasonably high levels of carbon. It can be hardened to around 62-64 HRC but note M4 is a carbon steel is not considered stainless with relatively low levels of chromium. So, while this is one of the best steels around for cutting, it has to be properly cared for and may develop a patina over time. Some manufacturers have resorted to coatings which do help but note they won’t last forever. Easy to sharpen?…erm, no. >> See knives with M4 steel.

In 2009, Crucible and Chris Reeve introduced an ever so slightly superior version of their excellent S30V steel and named it S35VN. By using a much finer grain structure and adding small quantities of niobium (hence the “N”) they were able to make the outstanding S30V easier to machine while improving toughness and ability to sharpen. In the real world, however you will find the two near-indistinguishable. Many would argue this is the ultimate in ‘mainstream’ knife steels and you would struggle to find any steel with better edge retention, toughness and stain resistance for the money. In 2019, a decade later, Crucible introduced CPM-S45VN which essentially incorporates an extra dollop of chromium for a modest improvement in corrosion resistance. >> See knives with CPM-S35VN steel.

Made by US based Crucible, CPM S30V (often simply referred to as S30V) steel has excellent edge retention and resists rust effortlessly. It was designed in the US and is typically used for the high-end premium pocket knives and expensive kitchen cutlery. The introduction of vanadium carbides brings extreme hardness into the steel alloy matrix. Dollar for dollar, this is generally regarded as one of the finest knife blade steels with the optimal balance of edge retention, hardness and toughness. Note S30V now has a slightly better looking brother in S35VN which is distinctly similar but easier for manufacturers to work with thanks to niobium. Still, S30V is pretty common these days and one of our favorites. >> See knives with CPM-S30V steel.

A relatively hard steel which is considered an upgraded version of 440C through the addition of Molybdenum. This achieves superior edge holding compared to 440C while retaining similar excellent levels of corrosion resistance despite having less Chromium. It has decent toughness good enough for most uses and holds an edge well. Not too difficult to sharpen with the right equipment. You’ll find a lot of quality pocket knives from top manufacturers like Benchmade using 154CM steel. You may also see CPM 154 which is a powder version of the same alloy produced much differently using Crucible Particle Metallurgy (Sweden’s Damasteel also produces a similar grade in RWL-34). The Particle Metallurgy process makes finer carbide particles resulting in a slightly superior steel that’s tougher and with better edge retention … but whether the average user can tell the difference is arguable.

This steel can be thought of as the Japanese equivalent to the US made 154CM. Accordingly, it has very similar properties and characteristics to the 154CM and in general represents a high quality steel which has become very popular with knife makers. ATS-34 has great edge retention but is actually a little less rust resistant than the lower-range 440C steel.

D2 steel is a tool steel often referred to as “semi-stainless” as it falls just short of the required amount of chromium (13%) to qualify as full stainless yet it still provides a good amount of resistance to corrosion. On the flip side D2 steel is much harder than other steels in this category such as 154CM or ATS-34 and as a result holds its edge a little better. That said, it’s not as tough as many other steels and exponentially tougher to sharpen. In fact, you really need to be a master-sharpener to get a fine edge on D2.

The VG-10 steel is very similar to 154CM and ATS-34 with slightly more chromium for enhanced corrosion resistance but also contains vanadium which makes it marginally tougher than these two. It originated not too long ago from Japan and has been slowly introduced into the American market by respect knife makers like Spyderco. It’s relatively hard and can get extremely sharp while also demonstrating reasonable toughness.

H1 steel from Japan’s Myodo Metals is basically the ultimate in corrosion resistance and essentially does not rust. The epitome of true stainless steel. Naturally, this comes at a price and that price is edge retention which is relatively poor. So, while excellent for diving it’s a non-starter for most EDC use. Very expensive stuff.

N680 steel contains about 0.20% nitrogen and over 17% chromium making it extremely corrosion resistant. If your blade will be in frequent contact with salt water for example then this is the steel for you. It’s also a fine grained steel that can take a very fine edge. Consider it a cheaper alternative to H1 steel with decent edge retention but it won’t hold an edge as long as say, 154CM.

Once considered the high-end in US knife steels, 440C is a good all-round steel that has now been overshadowed by many of the newer super-steels on the block. This is a stainless steel commonly used on many mass-manufactured pocket knives and represents a solid affordable all-round choice. It’s reasonably tough and wear resistant but it really excels at stain resistance. Holds an edge better than it’s 400-series counterpart 420HC but at the expense of some corrosion resistance. The 440C blades can be sharpened relatively easily. It has the highest levels of carbon and chromium in this group.

AUS-8 steel is Japanese made and extremely similar to 440B steel which is slightly more resistant to rust and corrosion than 440C but less hard. It’s also similarly tough but may not hold its edge as well as some of the more premium steels which carry a greater degree of carbon. Remember, more carbon means more hardness and edge holding. Real easy to sharpen and takes a razor edge.

Created at Spyderco’s request, CTS-BD1 is a vacuum-melted stainless steel from US based Carpenter that is often likened to AUS-8 and 8Cr13MoV with many putting it slightly ahead of those two based on superior edge holding. With slightly more chromium it also achieves better corrosion resistance. CTS-BD1 has mid-sized chromium carbides (hard, wear resisting particles) it takes an edge relatively easily but not on par with the wear resistance of high carbide steels like 154CM.

The MoV (or Cr) series of steels originate from China and comparable to AUS-8 but containing slightly higher carbon content. You typically get great value for money with this steel and good manufacturers like Spyderco have mastered the heat treatment process to bring out its best.

The 14C28N stainless steel from Swedish manufacturer Allemia (formerly Sandvik Materials Technology) is considered an upgrade to their 13C26 described below. In fact, Kershaw asked Allemia (then Sandvik) to make their 13C26 steel more resistant to corrosion and the result was 14C28N. In the lab you’ll find slightly more chromium and less carbon in the 14C28N but the real secret is the addition of Nitrogen which promotes corrosion resistance. Overall a very impressive mid-range steel that can be made extremely sharp. Arguably the best budget knife steel and quite possibly the best steel you’ll find on a sub-$30 production knife.

Very much like 420HC but with slightly more carbon which results in enhanced levels of wear resistance and edge retention but suffers from weaker anti-corrosion properties.

Generally considered the king of the 420 steels, 420HC is similar to 420 steel but with increased levels of carbon (HC stands for High Carbon) which makes the steel harder. Still considered a lower-mid range steel but the more competent manufacturers (e.g. Buck) can really bring out the best in this affordable steel using quality heat treatments. That results in better edge retention and resistance to corrosion. In fact, this is one of the most corrosion resistant steels out there, despite it’s low cost. You’ll find it mostly on budget blades (< $50) and multi-tools.

This is Allemia’s version of the AEB-L steel, originally developed for razor blades. Close comparison to 440A steel with a higher carbon to chromium ratio making it generally a little harder and wearable at the expense of corrosion resistance. Still, in real world applications it’s difficult to tell them apart and they tend to perform very similarly. Allemia later came out with 14C28N which is a slightly improved version of 13C26.

This is the most popular 10-series standard carbon steel (about 1% carbon) with low corrosion resistance and average edge retention properties. Why would you want 1095 steel? The appeal here is 1095 is a tough steel that’s resistant to chipping, it’s easy to sharpen, takes a crazy sharp edge and is inexpensive to produce. This makes it desirable for larger heavy duty fixed blades and survival knives which are going to be subject to more abuse than your typical EDC. Many manufacturers will coat their 1095 knives to delay the onset of any corrosion but a simple oil treatment will do the trick.

The 420 steel is on the lower end of the quality spectrum but still perfectly fine for general use applications. It has a relatively low carbon content (usually less than 0.5%) which makes for a softer blade and as a result will tend to lose it’s edge quicker than higher end steels. Blades made from 420 steel will rapidly lose their sharp edge over a relatively short time period. That said, it’s typically tough with high flexibility and extremely stain resistant but it is not particularly resistant to wear and tear. As you would expect, knives made from this type of steel are generally low priced, mass produced items.

Japanese made equivalent to the 420 series steel. A soft steel that’s generally low quality with relatively little carbon content but it resists corrosion reasonably well.

Other popular steels

In today’s fiercely competitive market the ultimate steels rarely retain their crown for long. Manufacturers consistently push the boundaries of science and technology to introduce superior alloys to the marketplace and boost profits. I remember the days when 440C was king, an impressive steel now relegated to the budget category. Sure, marketing plays a huge role today with companies using slick tactics to convince consumers that their latest steel is even better than the last. Truth is, it’s becoming increasingly difficult to evaluate these steels objectively as the incremental performance gains become indistinguishable and almost impossible to quantify outside of the laboratory. Still, here’s my take on some other steels which are popular among knife enthusiasts but still relatively rare in the marketplace.

Maxamet

Maxamet is the latest high speed powder steel from Carpenter (aka CarTech). Its an extreme alloy with insane hardness and tremendous edge retention while still retaining a reasonable amount of toughness but at the expense of corrosion resistance (it’s not stainless). While it wasn’t designed to compete with Crucible’s chart topping CPM-S110V steel, many knife nerds like the compare the two. So, how does Maxamet compare against CPM-S110V? Well, it’s largely still up for debate but from my experience Maxamet matches S110V in edge retention but falls short on corrosion resistance (it’s not stainless). Both are ridiculously difficult to sharpen. You’ll find Maxamet on some Spyderco offerings like the Native 5 and Manix 2.

Cru-Wear

Cru-Wear is a Crucible tool steel which can be thought of as a modification of D2 steel by dialing down the carbon and chromium while jacking up the vanadium and tungsten levels. Vanadium carbides beat out chromium for hardness and and lower carbon levels make for a tougher steel. So, now it becomes comparable to CPM-3V and M4, with excellent toughness and thus resistance to chipping in knives. Bottom line is, CruWear is offered as a balance between 3V and M4. It’s tougher than M4 but won’t hold an edge as long, while being less tough than 3V but holds and edge longer. Basically a good balance of toughness and wear resistance. Currently being offered by Bark River Knives, Jake Hoback, Spyderco.

CPM-MagnaCut

MagnaCut was introduced in 2021 and the brainchild of knife steel guru Larrin Thomas who designed the steel specifically for knives. Produced by Crucible, it’s a powder metallurgy steel whose alloy composition is not necessarily overly complex but the steel exhibits very interesting and fairly unique properties. It provides an excellent mix of toughness and wear resistance while also maintaining high levels of corrosion resistance. How so with under 11% chromium? The key is eliminating the chromium carbides and maximizing free chromium through an optimal chromium-carbon balance (basically the opposite phenomenon we describe with ZDP-189 above). This and the super fine structure of MagnaCut put it in the same league as CPM-CruWear and CPM-4V for toughness and edge retention while eclipsing the likes of CPM-S45VN and CPM-S110V in corrosion resistance. What’s the catch? Well, availability is extremely limited and prices are accordingly high…for now.

Knife Steel Performance Charts

Here are my rankings for edge retention, corrosion resistance, Rockwell hardness and toughness.

![]()

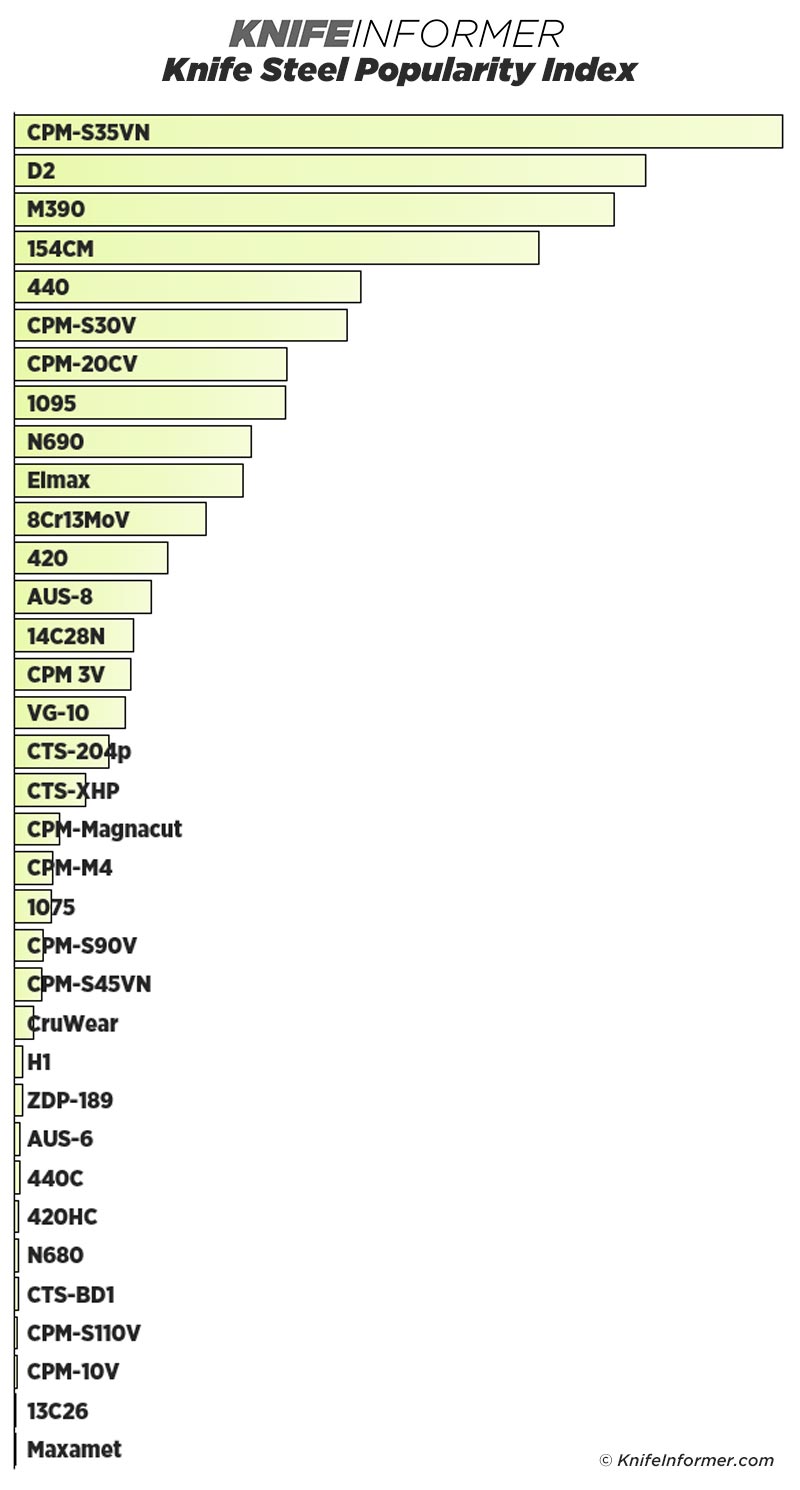

Steel Popularity

Our knife steel popularity index shows you the relative popularity of different steels currently used in folding knives production by the major manufacturers. This index is impacted heavily by factors such as consumer preference and production costs.

Knife Steel Elements

Alloying elements are an important ingredient vital in getting the best steel for the job. Here’s a brief description of their impact on the resulting steel’s properties. For more information see our knife steel composition guide.

| Element | What it contributes |

|---|---|

| Carbon | |

| Hardness, Edge Retention |

| Chromium | |

| Corrosion Resistance, Hardness |

| Molybdenum | |

| Toughness |

| Nickel | |

| Toughness |

| Vanadium | |

| Hardenability, Wear Resistance |

| Cobalt | |

| Hardness |

| Manganese | |

| Hardenability, Strength, Wear Resistance |

| Silicon | |

| Hardenability, Strength |

| Niobium | |

| Toughness, Wear Resistance, Corrosion Resistance |

| Tungsten | |

| Toughness, Wear Resistance |

| Sulfur | |

| Machinability |

| Phosphorus | |

| Hardness, Corrosion Resistance |

| Nitrogen | |

| Hardness, Corrosion Resistance |

| Copper | |

| Deoxidation |

| Aluminum | |

| Deoxidation |

| Boron | |

| Hardenability |

| Lead | |

| Machinability |

| Selenium | |

| Machinability |

| Tantalum | |

| Ductility, Hardness, Wear Resistance |

| Zirconium | |

| Toughness, Ductility |

What are CPM steels?

CPM stands for Crucible Particle Metallurgy which is a process for manufacturing high quality tool steels. American Crucible Industries is the sole producer of CPM steels which are formed by pouring the molten metal through a small nozzle where high pressure gas bursts the liquid stream into a spray of tiny droplets. These droplets are cooled, solidified into a powder form and then hot isostatically pressed (HIP) where the powder is bonded and compacted. The trick here is that the HIP process ensures each of the fine particles have a uniform composition without any alloy segregation. All this results in a steel that has improved toughness, wear resistance and can be ground and heat treated with maximum effect.

Austenitic vs Martensitic Steel

Austenitic steel contains high amounts of nickel (around 8%) which makes it non-magnetic and relatively soft making it generally undesirable for knife making. However, the benefits of Austenitic steel are its toughness and superior corrosion resistance from high levels of chromium making it perfect for everyday items like forks, spoons, kitchen sinks, etc. Martensitic steel contains less chromium while still meeting the criteria for stainless steel but very little nickel thus making the steel magnetic. What really sets martensitic steels apart is higher levels of carbon which allows for the formation of Martensite, an extremely hard structure making it ideal for knifemaking. Steel manufacturers can transform austenite into martensite through rapid quenching.

What about Damascus steel?

Damascus steel originates from the middle east from countries like India and Pakistan where it was first used back in good old “BC” times. It’s instantly recognizable as it bears a swirling pattern caused by the welding of two different steels and so often referred to as “pattern-welded” steel (not to be confused with Wootz steel which is only similar in appearance). There are many myths about the strength and capabilities of Damascus steel but today it is largely popular because of its aesthetic beauty. Mostly for collectors only.

Are all blades from the same steel alike?

Absolutely not. A massive factor in how a blade performs comes from Heat Treating. In transforming the ‘raw’ steel into the finished blade each manufacturer will heat treat the steel to bring out the best in its inherent characteristics. Heat treating is complicated and it requires skill to bring out the very best that the steel can offer. So, a CPM-S30V knife from one manufacturer may perform very differently to that from another.

Other considerations

Remember, blade steel is not everything. Knife buyers should beware getting caught up in researching the perfect steel type as it is not by itself the only thing that dictates how a knife will perform. Steel analysis has become somewhat scientific that it’s easy to get caught up in the maze of statistics. Note – just because a blade is made from the premium or high-end steels listed above does not automatically mean it’s “better” than the lesser steels. The heat treatment techniques used by the manufacturer as well as the design of the blade itself play a huge role in the ultimate outcome of knife performance!

In reality, all modern steels will perform well enough for most users so consider spending more time on other aspects of the pocket knife such as how the knife handles and other features.